Maximizing Your Craft: Mastering the IQ Vise Jaws™ – Sure-Fit™ for Optimal Results

Unlocking the Potential of IQ Vise Jaws – Sure-Fit

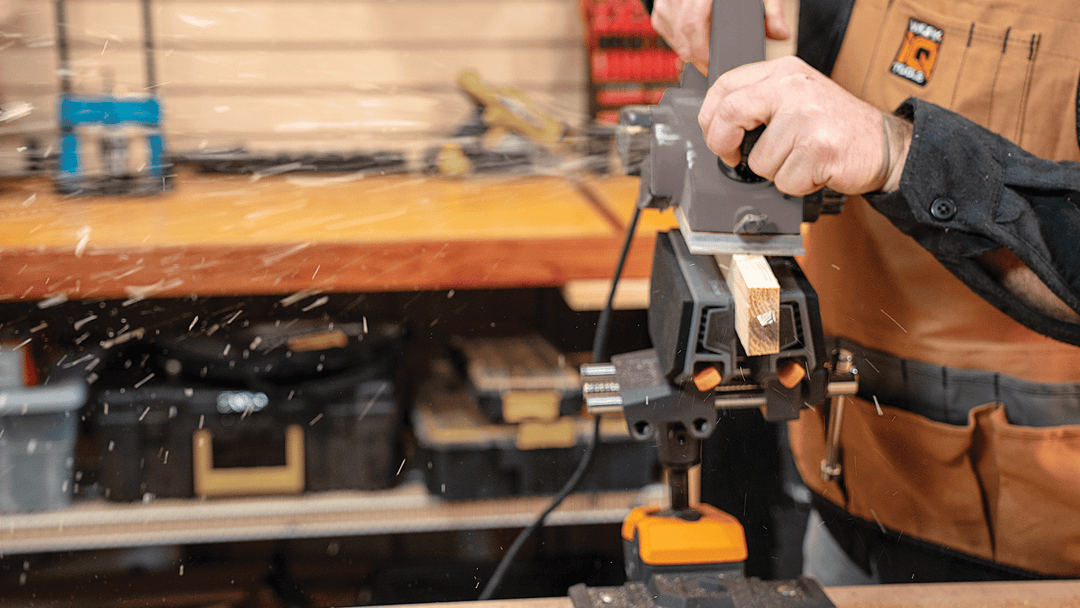

The IQ Vise Jaws – Sure-Fit are a hallmark of versatility in the world of precision crafting and DIY projects. Understanding how to maximize their potential is crucial for anyone keen on enhancing their workbench capabilities. This blog delves into practical tips and techniques to help users leverage the unique features of the Sure-Fit for a wide range of applications. Whether you are a seasoned professional or a passionate hobbyist, these insights will elevate your craftsmanship to new heights.

Expert Techniques for Diverse Materials

One of the most significant advantages of the IQ Vise Jaws – Sure-Fit is the adaptability to various materials and shapes. For instance, when dealing with delicate items or fine furniture, the non-marring compression-foam surface is ideal. It provides a secure grip without leaving any marks or indentations. Conversely, for more robust items like metal pipes or tubing, the multi-grooved nylon surface offers a firm hold, ensuring stability during intricate operations like soldering or cutting. Understanding which side of the jaw to use for specific materials is key to achieving the best results.

Maintenance and Care for Longevity

Maintaining the integrity of your IQ Vise Jaws – Sure-Fit is essential for their longevity and effectiveness. Regular cleaning of the compression-foam and nylon surfaces ensures they remain free of debris, which could compromise their grip. Additionally, inspecting the jaws for any signs of wear or damage, especially after handling heavy or abrasive materials, is crucial. Proper storage is also essential; keep the jaws in a dry, dust-free environment to prevent any degradation of the materials, ensuring they remain ready for your next project.

Creative Applications for Enhanced Productivity

Beyond traditional uses, the IQ Vise Jaws – Sure-Fit can be employed in creative ways to solve unique challenges. For example, the compression-foam side can be used for holding irregularly shaped objects like custom-made parts or sculptures, providing stability without risk of damage. The grooved nylon side is excellent for holding cylindrical objects at precise angles, invaluable for tasks like detailed painting or assembly work. Experimenting with different orientations and positions can lead to innovative solutions for complex projects.

Leave a comment